Let me refresh you where this project begins.

With drawing that I will use continually as references throughout the construction.

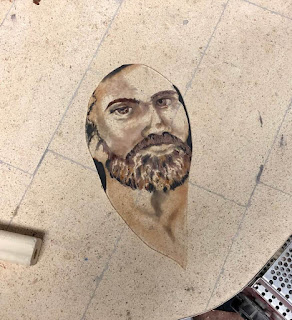

There are portrait drawings that are used for staining the faces for the final window. As well as reference for cutting the garments that will go in place.

First the faces need to be completed before the unit can begin final stages of construction.

In the first staining the reference marks are laid on the glass. The stain is crushed glass powder that is fired at high temperatures in a kiln that melts the crushed glass into the substrate glass leaving the design.

successive firings doing the same thing will darken the image.

The process is continued through several firings getting the face darker.

And darker.

And darker.

Where the piece rests at this time. On the light box, I can judge how the sun might come through and if the shading is too light still, or right.

He will need another stain treatment and kiln firing but, I can begin to add more character to his features as, he is almost dark enough.

I am working on the other two faces and the dove getting them to the finished stage and then we begin cutting glass for the rest of the unit.

Thank you for following along.

♥